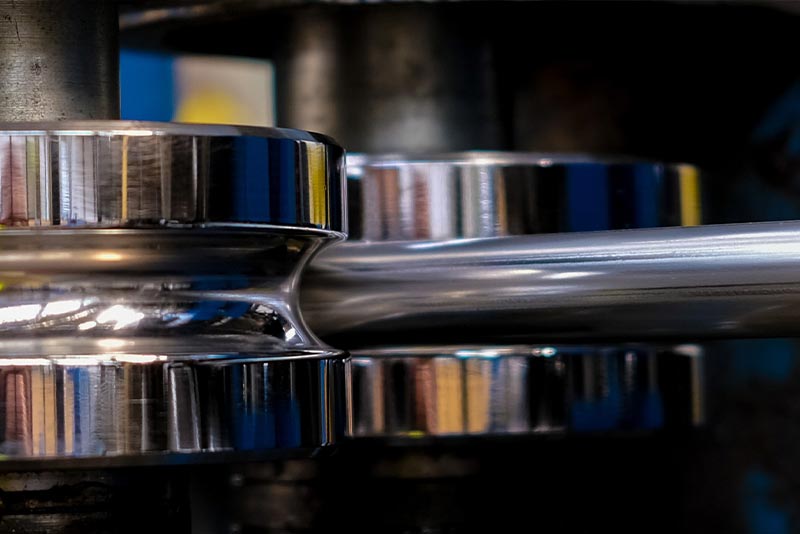

Welded Tube Manufacturing

We manufacture quality TIG Welded Tube from our facility in the UK

TIG Welding To Ensure Superior Metallurgic Quality

Single torch TIG (Tungsten Inert Gas) welding using a range of specialist welding gases within an inert atmosphere. Weld bead controlled.

Size Range

*Subject to O.D/WT combination.

Tube Specifications

Energy Tubes’ Full List of Tube Specifications

The following table lists the full specifications of tubes that we can produce. As with all of our products and services, if you can’t initially see the product you require then please contact our sales team and we would be more than happy to lend our expertise.

Tubes can be rolled in materials: 321, 304, 304L, 316, 316L, 800, 825, 600 & Titanium, Monel 400

Format

- Straight Length Tube

- Coiled Tube

- Custom Perforated Tube

Heat Treatment

- Bright Annealed Tube

- Black Oxidised Tube

Calibration

- Cut-to-length tube 25MM upwards

- Deburred Ends

- Chamfered Ends

Finishing

- Dull

- Satin

- Bright

- Mirror & Super Mirror Polishing

Testing & Manufacturing Specifications

View our Quality procedures to find out more.

Materials

View our material range to find out more.

Request a Quote today

Call us on (+44) 1902 671 222 email sales@energytubes.com or fill in a Quote Request below.